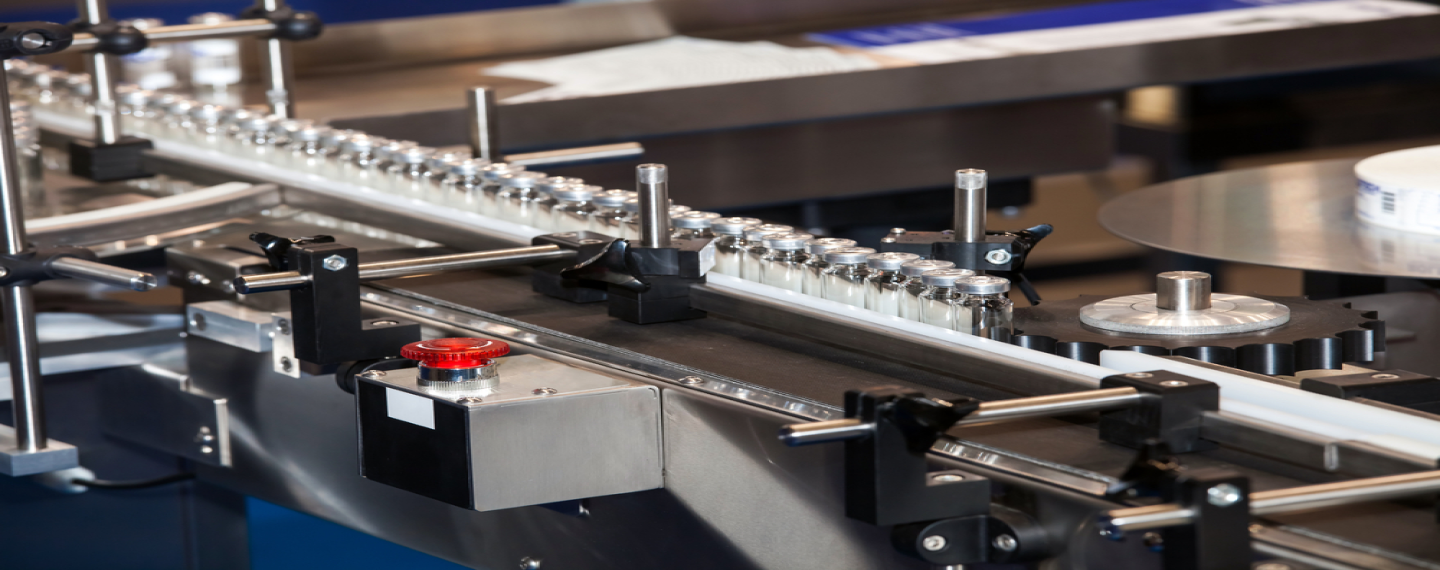

Pharmaceutical Industry

S-Node to the pharmaceutical industry revolutionizes equipment management by providing comprehensive monitoring solutions, enabling efficient control and optimization of processes, ensuring timely delivery, and maintaining competitive pricing.