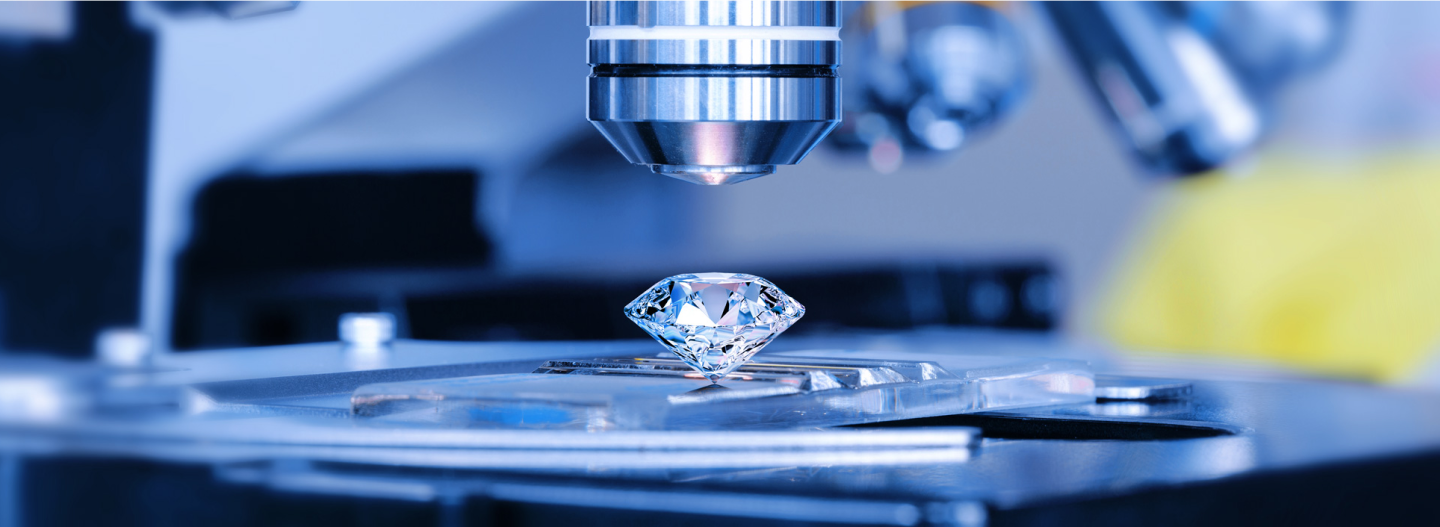

Lab-grown diamond Industry

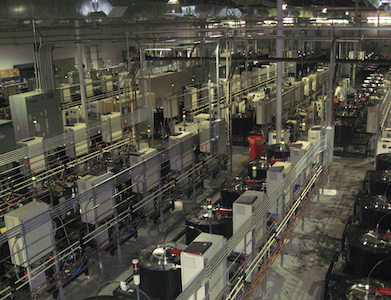

In the lab-grown diamond industry, S-Node enhances the production process by providing real-time monitoring and precise control, ensuring optimal growth conditions for CVD lab-grown diamonds, resulting in high-quality and cost-effective diamond production.